7 Major Onsite Tests Checklist for Disposable Latex Gloves Inspection in China

How to process onsite tests for disposable latex gloves inspection in China? TESTCOO has a wide range of capabilities for disposable latex glove inspection to support manufacturers, distributors and retailers in ensuring their disposable latex gloves?comply with industry and performance standards. Here is a guide to estimate disposable latex gloves, as well as nitrile gloves, vinyl gloves or medical grade gloves.

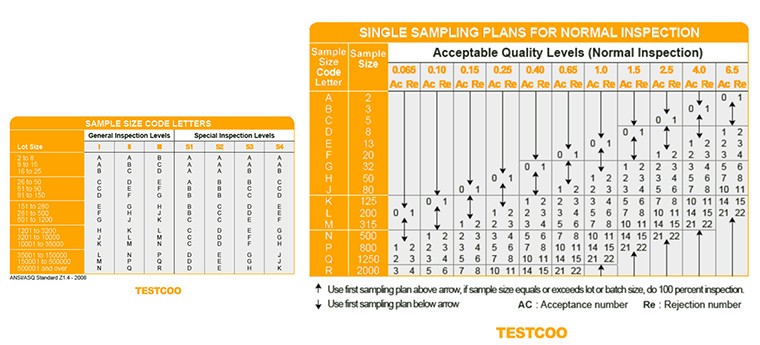

For gloves inspection, how to determine the right sample size and acceptance number?

A key quality measurement for disposable latex gloves is AQL, or Acceptable Quality Level. AQL will help you monitor and avoid batches of unsatisfactory products. So how is AQL applied in practice? According to AQL, there are three kinds of defects, critical defects, major defects and minor defects. Importers usually apply AQL of 0.0 for critical defects, AQL of 2.5 for major and AQL of 4.0 for minor defects. For example, to meet an AQL of 2.5, from 200 sample gloves randomly picked from the bulk 10,000 production, no more than 10 gloves can fail the quality inspection. For more details, please refer to: How to read AQL table?

7 major onsite tests for disposable latex gloves inspection in China

TESTCOO performs the following major onsite tests for disposable latex gloves:

1. Product view

2. Product Size / Weight Measurement

3. Water leakage test

4. Barcode scan test

5. Elongation test

6. Special function test

7. Transportation drop test

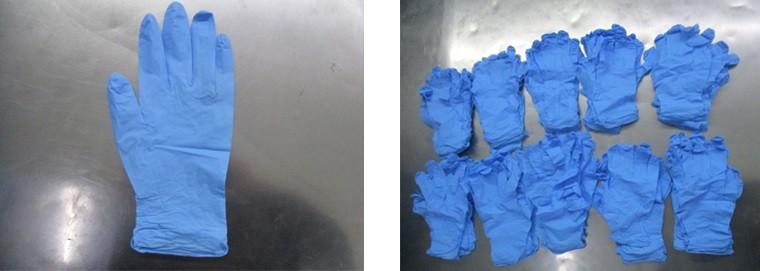

1. Product view

The color of the gloves should be clear and uniform. If you see cloudiness or variations in color, this implies low-quality disposable glove fillers are used to save money during manufacturing.

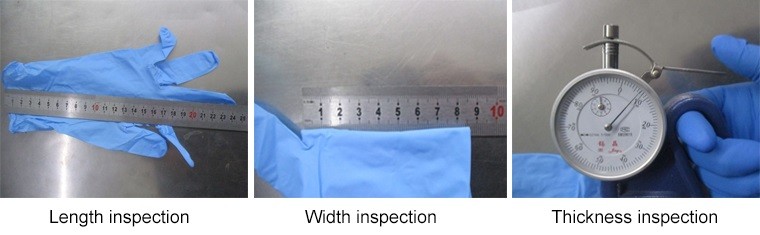

2. Product Size / Weight Measurement

Product size and weight measurement are performed to make sure that each pair of disposable latex glove is in standard size and quality.

3. Water leakage test

Water leakage test is crucial for disposable latex gloves inspection. In this test, each gloves are filled with water at room temperature, secured at the cuff tightly and hung vertically for two minutes to check pinholes. If the water does not leak from the glove, it gets a “pass”.

4. Elongation test

Elongation at break test is also called “fracture strain” test or “tensile elongation at break” test. While it’s a destructive test as it shows how much force a material can take before failing, it’s significant in checking the function of the disposable latex gloves.

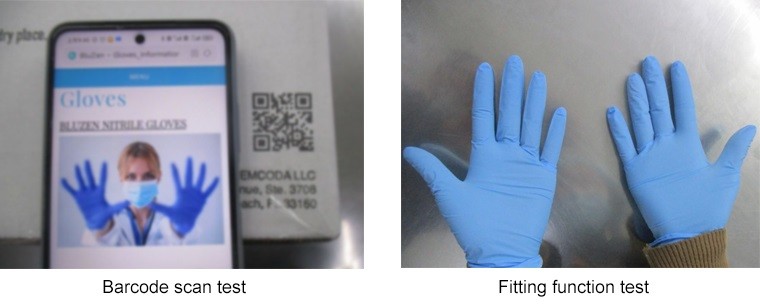

5. Barcode scan test

This test is to ensure the product barcode is printed correctly and can be scanned by mobile phones.

6. Special function test

Usually it is to check the function after fully assembling according to customers’ special acquirement, for example, the fitting test.

7. Transportation drop test

Transportation drop test, or free fall test, serves as an important indicator of product quality and durability. It is performed to make sure the products stay in its original condition from manufacturing to implementation.

Quality inspection is crucial for your disposable latex gloves

As we know, disposable latex gloves are in high demand mainly used by healthcare professionals, front-line workers in grocery stores or restaurants, as well as the general public. Choosing the appropriate disposable latex gloves for your specific work environment is essential.

Today, using a third-party inspection company is convenient with an excellent price, who can help to ensure your products meet your customers’ expectations including materials, style, function, etc. As a third-party inspection company with intelligent management for quality assurance, TESTCOO aims to build the world’ s most influential third-party inspection service center. Contact TESTCOO and you can make an inspection order in 5 minutes and get your detailed report in 48 hours.

???????

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index