Factory Audit: How to do a VR Factory Audit?

As a crucial part of the new supplier vetting process, a factory audit helps you to evaluate a potential supplier’s reliability, capabilities and warns you of any key risks that might prevent them from meeting your needs. You can then be on the basis of the audit report to help make the decision on whether to work with them or not. If you remain ready to further purchase, rectification solutions from the factory audit would be a big help.

There are a number of different types of factory audits that you may consider, though, so which is right for you?

VR factory audit, your choice in 2022.

What is a VR factory audit?

VR factory audit is a more advanced way for new supplier assessment. TESTCOO VR Factory Audit Service makes it possible for retailers, importers, and buyers to experience like on-site by yourself by applying VR panoramic camera technology.

Sitting at office, you may easily get a 360-degree view of the factory. With professional comments by our inspector, every detail can be spotted on your screen. This self-developed platform ensures the quality, compliance, and safety of your products through the global supply chain as well as a healthy society and environment where the production is conducted.??

Benefits that conduct a VR factory audit from Testcoo?

1. Full View:?You can see the actual capacity and the site management ability through the full view visually.

2. Real Presentation:?Health and safety situation on the work floor can be reflected really.

3. Specialized Comments:?H&S risks, weakness and strength of the management can be understood by clients easily through those full view and specialized comments.

4. Visualized Experience:?Avoid only part or selected facts displayed by ordinary photos.

5. Anti-Bribery:?The real scene and offsite comments will let no onsite conclusion can be made, so that the integrity can be ensured on maximum?possibility.

How to do a VR factory audit?

1. Documents verification

The auditor does not only ask for basic financial information. He requests the factory’s official licenses and certifications, discover the product typology of the products and manufacturing process, and looks for the other main client orders.

2. VR factory audit conducting

The auditor observes the number and the position of the buildings while entering the gate to get a general impression of the factory. It will be helpful for the planning of VR factory audit.

-Observation of the production area

With 3D camera, discover every corner of the production area in stunning details. The auditor checks the factory building, office, lab, IQC inspection room, raw material warehouse, production process, packing line, assessment workshop, finished good warehouse, dust free workshop, staff restaurant, staff dormitory, sample room, with factory representative for the function of each area marked on the layout.

-Verification of the quality system

The auditor follows a checklist loosely based on ISO9000 series. He typically observes the verifications of incoming materials, in-process products, and finished goods. The objective is to look for holes in the factory’s quality system, and to evaluate their reliability. Read?Testcoo quality assessment?to learn how quality system works.

-Social compliance issues

The auditor checks whether the factory respects its country’s regulations, and some other criteria from a standard such as SA 8000 or Sedex. Verifications focus on pay records, worker interviews, observations in the workshop, etc.

More Social compliance Audit:?Supply Chain Assessment: Why Should You Care About Social Compliance Policy?

This is often conducted as a separate audit. The objective is usually to avoid public relations risks for the importer or the retailer.

3. Production inspection

Sample 20 pieces of products at the end of the packing line to conduct workmanship inspection, and take video for around 20 seconds for the inspection and take photos for the defects found.

4. Reporting

The audit review the integrated 3D photos, point out the NCs found of each scene and write the comments down. A VR factory audit report can be integrated based on upload factory profile and QMS parts, 3D photos, 3D photos, 2D photos and video of inspection, comments on integrated 3D photos.

5. Feedback following

Follow the feedback from clients and take further action if necessary.

What is a VR factory audit report?

VR factory audit report generally contains two parts, PDF factory assessment report and VR factory assessment report. PDF report can be download by click the “report "icon. This PDF report has same structure with other traditional audit report. Enter the full view mode that is VR report when you click the “overview "icon.

1. PDF Report

Part A:?Basic information of the audit: location, areas, manpower, production capacity, main process, main clients and overall summary.

Part B:?Quality Management System (QMS) part: inspection criteria, inspection record, measuring equipment control etc.

Part C:?Production Field Audit part: contamination risk, product protection, and fire safety, electrical safety, machinery safety, child labor, force labor etc.

Checkpoints and comments of QMS and production field audit are same as full view report.

Part D:?Additional photos related to QMS and other useful information.

2. VR Report

-Summary:?How many buildings and floors there are in the factory can be seen visually through the building model.

All work floors, the function areas, a summary of corresponding area will be displayed, as well as the location of this area will be lighted at the same position of the building model.

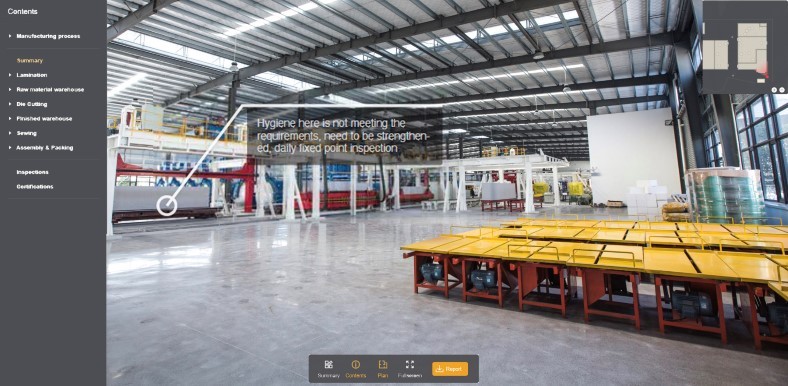

-Contents:?The full view of the factory. Following the arrows on the VR report, you can go to each scene of the factory to check every corner of the work floors as you are on site.

The dashboard at the left is full view photo, click each of the comments, you can see the scene with auditor's comments.

-Plan:?The floor plan shows the position and direction of this scene in whole function area.

Check a?Sample VR Factory Audit Report Now!

???????

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index