Fabric Inspection | Four Point System

Fabric inspection is an essential QC assessment which can be used to minimize the chances that fabric problems will only be detected on finished products. it is recommended that fabric inspections must be performed with fabric inspection machines prior to spreading the fabric for improved defect visibility and ensure that only passed fabrics will end up on the garment’s production lines. Learn more about fabric inspection:?Fabric Inspection in Textile and Apparel Manufacturing

The 4-Point System

The 4-Point System, a standard under ASTM D5430 – 07(2011) that specifies a method for establishing a numerical classification for grading fabrics from a visual inspection, is the most commonly used fabric inspection system in the garment industry. It may be used for the supply and adoption of fabrics with criteria and tolerance agreed previously between buyers and sellers.

This scheme does not assign a quality level to a product; instead, it assigns demerit point scores to defects to define them according to their seriousness levels. This method can rate any form of fabrics, whether it's grey or finished.

How the 4-Point System Works

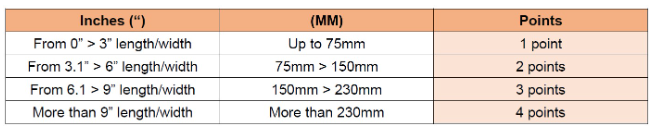

Owing to the scale, consistency, and importance of the defect, the 4-Point System assigns penalty points from 1 to 4. A single flaw may be granted?no more than 4 penalty points. Since the system is the same for all directions, a defect may be assessed in either the length or width direction. Only major defects are taken into consideration while minor defects are not penalized.

The total defect points are calculated for 100 square yards of fabric, and then based on the company’s predefined acceptance criteria, the fabric roll is graded.

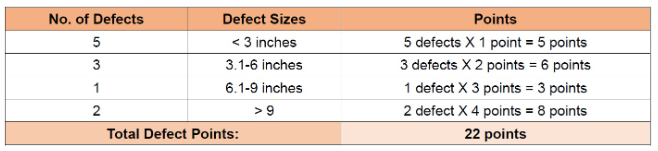

For example, assuming that after inspection of fabric roll of size 120 yards and width 45 inches, the following defects were found:

Total defect points per 100 square yard of fabric =?(Total defect points in the roll x 36 inches per yard x 100 yards) / (Fabric width in inch x fabric length in yards)

= (22 x 36 x 100) / (45 x 120) =?14.66 defect points per 100 square yards.

???????

Acceptable Level

Some factories establish that up to 40 points per 100 square yards is acceptable, however, in the apparel and textile industry, apparel brands and buyers set their own standards for acceptable points.

TESTCOO conducts plenty of inspections for textiles and fabrics, as well as for garments and footwear in China, India, Vietnam, Malaysia, Thailand and Bangladesh. Full-time inspectors guarantee reliable professional inspection for your products while conducting specific on-site tests to ensure the long-term quality of the goods and ultimately your reputation.

For a?sample report on the fabric inspection, please feel free to contact us at service@testcoo.com

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index