EN 17885-New European Standard for Candle Accessories

EN 17885, new specifications for fire safety and product safety labels for candle accessories, helps to ensure a reasonable degree of safety during use.

A new European standard concerning fire safety and safety information for candle accessories, EN 17885, was published at the end of August 2023.

Accessories intended for use with candles, including but not limited to candle holders, candle burners, lanterns, food warmers, oil burners, candle rings, shades and toppers must comply with the safety requirements and provide suitable safety information for the consumer to ensure a reasonable degree of safety during use, thereby improving personal safety and reducing the risk of fires, deaths and injuries.

The Safety Requirements Specified in EN 17885 Include:

1. Flammability

When tested, the accessory shall have a burn time of less than or equal to an average of 30 s for three tests per component and the burn time for any one test shall not exceed 60 s. Flames shall not spread over the entire accessory.

2. Stability

When tested, the accessory and the used candle(s) shall not tip over when placed at a (10 + 0,2)° incline from horizontal.

3. Fire safety

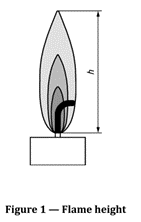

When tested, the candle shall exhibit no secondary ignition for more than 10 sand the flame height of all candle types, except tea lights, shall not exceed 75 mm. The flame height of tea lights shall not exceed 30 mm. Candle containers shall not crack or break at any time throughout the burning test. The candle accessory shall not break, crack or catch fire as a result of the test.

4. Surface temperature

(i) parts intended to be touched;

(ii) parts likely to be touched unintentionally;

(iii) parts likely to come into contact with other materials

*?Birthday cake candle holders that can hold only one candle and do not contain pyrotechnics are exempted from this requirement.

Test Equipment and Apparatus

1. Incline plane (fixed or adjustable) with an angle of (10 + 0,2)° from a horizontal level.

An anti-slip-surface like sandpaper may be used to help prevent the candle accessory from slipping during this test.

2. Measuring device, non-flammable with millimetre grading

3. Stop watch.

4. Flame Source, a post mix butane/propane stick lighter capable of producing a flame with a height of (40 +5)mm and width of (6 + 1) mm and capable to safely produce a stable flame at a downward and upward angle of 15° to 45° from horizontal level for at least 60 s.

The blue flame part should be approximately 10 mm in height.

5. Ring stand/clamp assembly

6. Thermometer.

7. Hygrometer.

8. Candles

9. Thermocouple, class 1 K-type thermocouple, thickness 0,5 mm.

10. Data collector, computer-controlled data logger capable of recording the temperature in intervals of max. 30 s.

Candle Quality Control Safety Labels

The manufacturer or importer of the candle accessory shall specify appropriate supplementary safety information for each candle accessory when necessary.

?

?

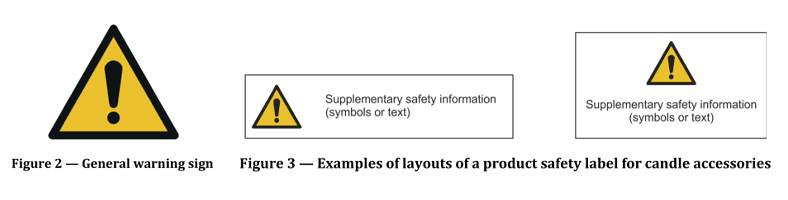

Regarding the safety information, it is mandatory for the safety label to include a general warning sign???and appropriate supplementary safety information symbols or texts, which must be:

-Minimum 5 mm in height for the safety symbols

-Given in their own national language or languages of the country in which the candle accessories are marketed

-In distinct contrast from its background

-Visible and legible on the candle accessory itself or on its packaging (note: If this is not possible in a safe manner due to the design of the product or packaging, the product safety label may be placed in a separate brochure or pamphlet packed with the candle accessory)

Conclusion:

Candles have accompanied humankind for more than 2 000 years serving above all as a light source Closely connected to the development history of the candle are the efforts made to improve its quality and its safety in use. As the function as decoration and not only as light source has increased, the causes of fires are often connected to inappropriate candle accessories and to inappropriate use by the consumer which have led to consumer concern for these issues.

Third-party inspection has become a key part of many candle importers’ supply chains. With an inspection team on the ground, you can see exactly how your products look without needing to personally visit the factory to check.

Testcoo supports retailers, manufacturers, distributors and suppliers in the quality inspection of candles.?Get in touch with Testcoo?candlequality control expertise now!

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index